How do you know when a space or surface is “clean”? Unfortunately, the human eye is not equipped to see at a microscopic level. It’s also not feasible to walk around and clinically test hygiene on all surfaces and equipment on a daily basis.

That’s why it is absolutely crucial to ensure that you have the right procedures, equipment and controls in place. Of course, there’s no such thing as having a scenario that is completely safe from risk. But, with adequate processes and a bit of expert advice, you can rest assured that you’ve put in place risk-resistant and preventative measures to keep your business environment germ-free and audit-ready.

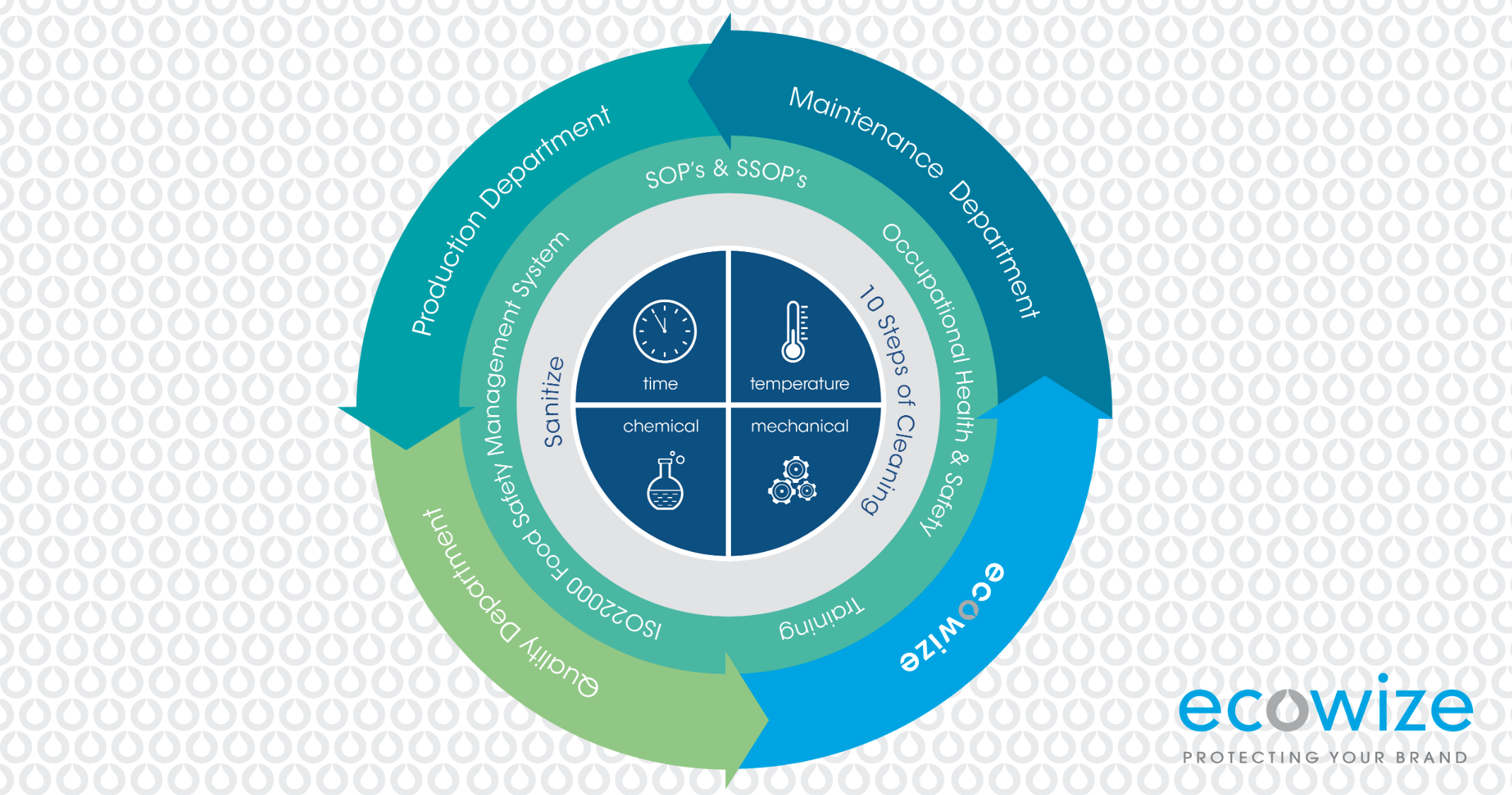

At the core of modern thinking around cleaning lies what’s known as “Sinner’s Circle”. Identified by Herbert Sinner over 60 years ago, it presents a winning formula for “clean”, comprising of four factors which need to be in sync.

Sinner’s Circle refers to the right chemicals + adequate mechanical or manpower action + optimal temperature + enough time spent. If one of these factors is missing, or decreased, your cleaning outcome is likely to be compromised. The correct balance of these four factors is required here to achieve the best result in the most cost-effective way.

In the food industry however, Sinner’s Circle is not enough, explains Mark Sterling, National SHEQ Lead at Ecowize. “Times have changed! Clean no longer means just visually clean; clean means visually clean, micro-biologically sanitized and audit-ready. Daily!”

This is why sanitization and food safety systems play such an important role in today’s cleaning methods, encircling Sinner’s Circle foundation – and building on it, to take cleaning to a whole new level. Because that’s the Ecowize way.

To help you achieve this, we’ve “made the circle bigger”, expanding on Sinner’s Circle to create a smart cleaning intervention (pictured below).

As you can see, Ecowize will equip their cleaning team with necessary training; upskilling in the area of the Ecowize 10 steps of cleaning (click here to read our case study on smart cleaning); the implementation of Standard Operating Procedures and Site-Specific Operation Procedures; and their certified ISO22000 Food Safety Management.

As you can see, Ecowize will equip their cleaning team with necessary training; upskilling in the area of the Ecowize 10 steps of cleaning (click here to read our case study on smart cleaning); the implementation of Standard Operating Procedures and Site-Specific Operation Procedures; and their certified ISO22000 Food Safety Management.

We’ll step in and empower your operation by augmenting our people-process-technology approach. This way of working looks for interventions that can be made with your staff, your systems and your technology to help you yield the most effective, affordable and consumer-safe solution for your operation.

Ready to make the circle bigger? Contact us and let’s talk about how we can clean up the meaning of ‘clean’ in your organisation – and take pristine to a whole new level.

Comments are closed.